SSM vs Bresle method

Soluble Salt Meter versus the Bresle Patch Method

The approved ISO8502-9 equivalent fully automated soluble salt meter establishes surface cleanliness on the job and determines salt contamination.

Equivalent to the Bresle test, the soluble salt meter will indicate contamination of soluble salts on blast-cleaned surfaces prior to coating but with the added bonus of a very short test cycle time. Till a few years people were forced to take these measurements with a 20 year old technique using patches. This was a tedious and time consuming task using a lot of ECO unfriendly expensive consumables. Differences in results lead to discussions and reasons for concern in the field.

The Bresle Method was first introduced in 1995 and has been widely accepted. However the method:

- Has a large variation in results due to the many manual process steps

- Is tedious & time consuming

- Leaves residue on the surface; Requires Post Clean-up Process

- Is costly; each measurement requires a new Bresle patch

- Requires manual record keeping

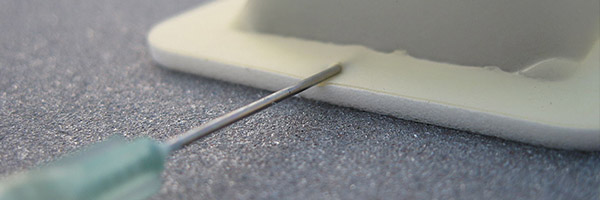

- Uses syringes in industrial practices

Since innovation cannot be stopped, the goals in developing the Soluble Salt Meter were:

- Improve the time, quality, and accuracy in field analysis

- Eliminate use of syringe needles

- Develop a paperless instrument

- Automate water dosing and washing system

- Eliminate consumables (patches and syringes)

- Exactly replicate the Bresle Patch protocol

- Eliminate residue left behind from Bresle Patches

The Soluble Salt Meter is the first approved ISO8502-9 equivalent method, which automates soluble salt measurements. The patented design provides a hand held paperless solution to measure the presence of soluble salts on flat and curved surfaces.

The Soluble Salt Meter (SSM) combines surface salt extraction and conductivity measurement in one tool, allowing convenient and ergonomic operation.

The hand held design provides a self-contained, easily transportable, unit for soluble salt measurements. Find out how you can save time and money on your salt measurements and ask for a price quote today.

The SSM test protocol exactly duplicates the Bresle process but with a higher accuracy and reproducibility. Measurements are automated and there are no consumables. The complete test sequence requires only less than a minute.

Pricing Find a reseller in your regionSide-by-Side comparison

The SSM test protocol exactly duplicates the Bresle process, except that measurements are automated and there are no consumables.

The complete test sequence requires only one minute. The SSM is approved as an authorized alternative to the Bresle patch method.

| Bresle Patch Method | Soluble Salt Meter | |

|---|---|---|

| Compartment Area | 1250 ± 13 mm2 (square).Can vary an additional 5% due to stretching | 1250 mm2 (circular). Fixed footprint |

| Attachment Method | Adhesive. Leaves residue; Requires post measurement cleanup | Magnetic. No effect on surface quality; Proven to seal over deep pits |

| Water Injection Method | Manually with syringe (3.0 ± ? ml). Prone to human error and injury | Automated and accurate with dispenser (3.0 ± 0.04 ml) |

| Dissolving salts from the surface | By rubbing the surface of the Bresle Patch. Duration and intensity inspector dependent | Automatic, according to fixed procedure and duration |

| Measurement | Remove solution with syringe and measure it with separate conductivity meter | Automatic |

| Recording | Manually on paper | Automatic storage in memory |

| Consumables per measurement | Bresle Patch and deionized water | Only deionized water |

Process measurement steps

BRESLE PATCH |

|

|---|---|

| Step #1 | Select Bresle patch, remove the protective paper and the punched-out material |

| Step #2 | Adhere patch to surface (attempting to minimize trapped air) |

| Step #3 | Fill syringe with 3ml deionized water |

| Step #4 | Inject half of the water into the patch |

| Step #5 | Reposition needle and evacuate air |

| Step #6 | Remove the needle from the patch. Holding the syringe with the needle pointing upwards, expel the air |

| Step #7 | Re-insert the needle into the compartment and inject the remainder of the solvent |

| Step #8 | Agitate Bresle patch with finger for 10-20 seconds |

| Step #9 | Extract solution using syringe |

| Step #10 | Transfer solution in syringe to Horiba B-173 meter |

| Step #11 | Take reading |

| Step #12 | Record reading by hand on QA sheet; NOTE: ISO 8502-6 dictates that during steps 3 to 10, it is essential that no solvent be lost from the patch or syringe. If any solvent is lost, the solution obtained shall be rejected. |

| Step #13 | Remove Bresle patch from surface |

| Step #14 | Wipe remaining water from surface with rag |

| Step #15 | Clean any adhesive remaining on surface |

| Step #16 | Clean and rinse out syringe |

| Step #17 | Clean Horiba meter. |

SOLUBLE SALT METER |

|

|---|---|

| Step #1 | Attach meter to surface |

| Step #2 | Inject deionized water into measurement chamber with one press of the dose bottle |

| Step #3 | Meter automatically agitates solution (~ 20 seconds) |

| Step #4 | Meter automatically takes reading, displays it on the LCD screen and stores values electronically |

| Step #5 | Wipe remaining water from surface after removing SSM |

| Step #6 | Flush meter by turning over and injecting water from dose bottle |